Double Girder Overhead Crane

- Load 5-450 ton

- Max Lifting Height 30m

- Warranty 3 years

- Color Customized

Product Description

Double Girder Overhead Crane

Electric double girder bridge crane is a common lifting equipment, which is widely used in factories, warehouses, docks, shipyards and other places. It has the characteristics of simple structure, convenient operation, safety and reliability, and is an indispensable and important equipment in modern industrial production. The main components of QD electric double-girder bridge crane include bridge frame, hoisting machinery, electrical system and so on. The bridge frame consists of two beams connected by beams to form a bridge-shaped structure. Lifting machinery includes cranes, carts, trolleys, etc., which can move freely on the beam to realize the functions of lifting and transporting items. The electrical system includes motors, controllers, cables, etc., which control the operation and stop of the crane to ensure the safety and stability of the crane.

Lifting Height:6-30m | Capacity:5-450 ton | Warranty:3 years

Span:0-35m | Working Class:A3-A5 | Control Method:Remote Cabin Control

| Capacity/t | Span/m | Work duty/IO | Lifting speed/ m/min | Rail |

| 5 | 10-40 | A5 | 13.3 | P43 |

| 10 | 8.5 | |||

| 15 | 7.9 | |||

| 20 | 7.5 | |||

| 32 | 6 | QU70 | ||

| 50 | 5.9 | |||

| 75 | 4.5 | QU100 | ||

| 100 | 4.2 |

Product Description

Product

Product Main Features

01:

Double Girder Design: The Double Girder Overhead Crane features a double girder design, which provides increased stability and lifting capacity compared to a single girder design

02:

High Lifting Capacity: The crane is capable of lifting heavy loads, ranging from 5 to 450 tons, depending on the specific model

03:

Large Span: The crane can be customized to have a span of up to 35 meters, allowing it to cover a large working area

04:

High Lifting Height: The QD Type Double Girder Overhead Crane can be customized to have a high lifting height, typically ranging from 6 meters to 30 meters

05:

Precise Control: The crane is typically controlled using a cab-mounted control panel or wireless remote control, allowing for precise and efficient control of the crane's movements

06:

High Working Efficiency: The QD Type Double Girder Overhead Crane is designed for high working efficiency, with fast travel speed and lifting speed

Safety Devices

- Overload protection: This device can detect and prevent overload situations. Once overload is detected, the crane will automatically stop working to avoid accidents

- Limit protection: This device, through the use of limit switches and travel switches, can limit the operating range of the crane to ensure that it operates within a safe range

- Anti-collision device: This device, through the use of anti-collision switches and bypass switches, can detect and prevent collisions between the crane and other objects to avoid accidents

- Emergency stop device: This device, through the use of emergency stop switches and power-off switches, can stop the crane quickly in case of emergency to ensure the safety of personnel and equipment

- Leakage protection: This device, through the use of leakage protection switches, can detect and prevent leakage to ensure the safety of the crane during use

- Overload protection: This device, through the use of overload protection switches, can detect and prevent overloading to ensure the safety of the crane during use

Parts Of Crane

About Us

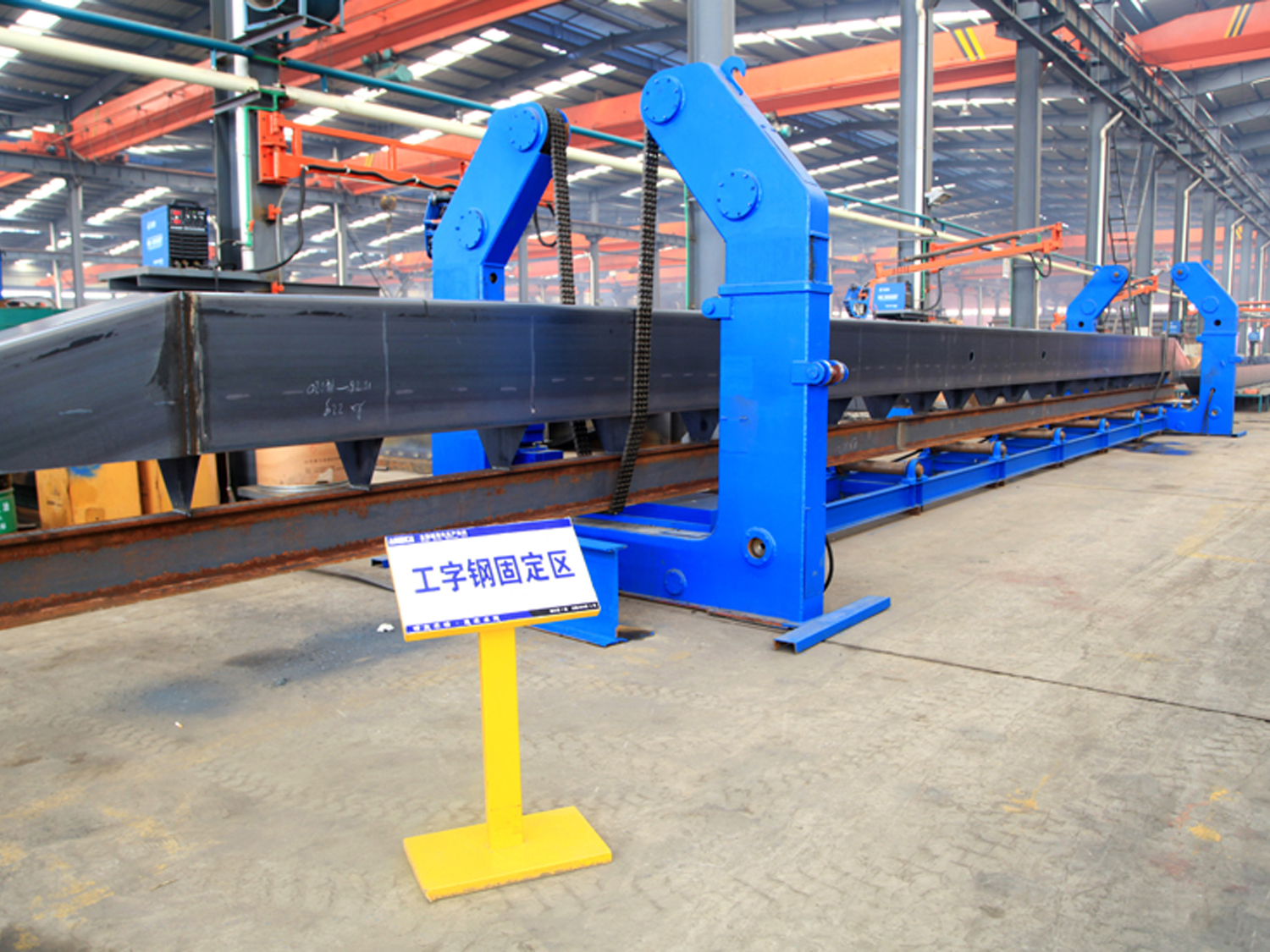

Our Factory

1

Production Workshop

2

Customer visit

3

Exhibition

4

ISO Certifiaction

5

CE Certifiaction

6

Our Services:

▶3 years warranty

▶Free distribution of wearing parts

▶Provide assemble videos before shipment

▶Technical support and field installation

Package and Delivery

Packing & Delivery terms:

▶Packaging: The components of the crane are packed in wooden crates, steel frames, or other suitable packaging materials

▶The packed components are then shipped via truck, rail, or sea, depending on the distance and destination of the delivery

FAQ

-

1How can I get a precise crane offer?

To providing you a precise crane offer efficiently, please kindly provide details as following:

Lifting capacity; material weight(unit as tonnage)

Lifting height; (unit as meter)

Crane span; the width of inquired crane(unit as meter)

Crane traveling length; when rail track/runway beam needed, traveling length shall be provided.

Working power; power source at site(unit as voltage, phase and Hz)

-

2Can I get your crane products with customized/personalized service?

A.Yes, Dowellcrane promise customized/personalized products are available for our clients all the time. Just freely let us know your special demands about the products, our engineering team will work on that.

-

3What should I do if I’m not able to install the crane after buying?

A.Freely contact us. Our engineering team available for oversea service with crane installation, inspection and commissioning.

-

4How long I can receive my crane products after my order placed?

A.Our production will be started once the payment confirmed. Below are timeline for whole procedure

-

5Do you have any additional service on warranty?

A. Yes, we provide “DowellCrae” service about the warranty, the warranty period will extend to two (2) years, full set of spare partsand working tools will delivered with crane for future replacement and maintenance.

FORM

GET THE BUSINESS TODAY

We really want to hear from you! Send us a message using the opposite table, or send us an email. We are

glad to receive your letter! Use the table on the right to send us a message