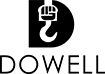

European Type Double Girder Overhead Crane

- Load 5-50 ton

- Max Lifting Height 30m

- Warranty 3 years

- Color Customized

| European Overhead crane | Span:10-50m | Capacity: 36-60 ton | Lifting Height:6-30m |

| Crane traveling Speed:20-40m/min | Working Class:A5/A6 | Control Method:Remote/Cabin Control | Warranty:3 years |

Product Description

European Type Double Girder Overhead Crane

European-style double-girder crane is a kind of bridge crane manufactured according to European design standards. It consists of two main girders, end car system, lifting trolley, control system and cab. It can effectively use the factory space, reduce the distance from the hook to the ground and the walls on both sides, reduce the weight of the whole crane, and save the factory cost.

European-style double girder cranes are suitable for medium-heavy and heavy-duty industrial fields, and can carry materials up to several hundred tons. It has many types, and it can be equipped with different spreaders, such as electromagnets, grabs, hooks, etc., according to different working environments and needs.

Main standards quoted: GB/T15362-92 Technical Conditions for Rubber tired Container Gantry crane, B/T/4783-94 Test Methods for Rubber tired Container Gantry crane, International Organization for Standardization ISO standards, European FEM, Japanese JIS standards.

Product Description

Product

Product Main Features

01:

The end beam is formed by welding rectangular steel pipe or steel plate, with high positioning and processing precision, equipped with double rim wheel set, buffer and anti-derailment device

02:

The main beam and end beam are connected by high-strength bolts to ensure the precision and smooth operation of the whole machine

03:

A maintenance platform (maintenance walkway) is arranged on the driving side of the main girder for easy maintenance

04:

The lifting trolley adopts European standard electric hoist, which has the characteristics of compact structure, low noise and high efficiency

Safety Devices

- Limit switches: These are devices that limit the motion of the crane by stopping it when it reaches a certain point

- Load sensors: These sensors detect the weight of the load being lifted and ensure that the crane does not exceed its maximum lifting capacity.

- Emergency stop buttons: These buttons are located at various points along the crane's control panel and allow the operator to stop the crane immediately in case of an emergency.

- Anti-collision devices: These devices prevent collisions between overhead cranes and other objects in the vicinity.

- Warning alarms: These alarms are used to alert workers in the area that the crane is in operation.

Parts Of Crane

About Us

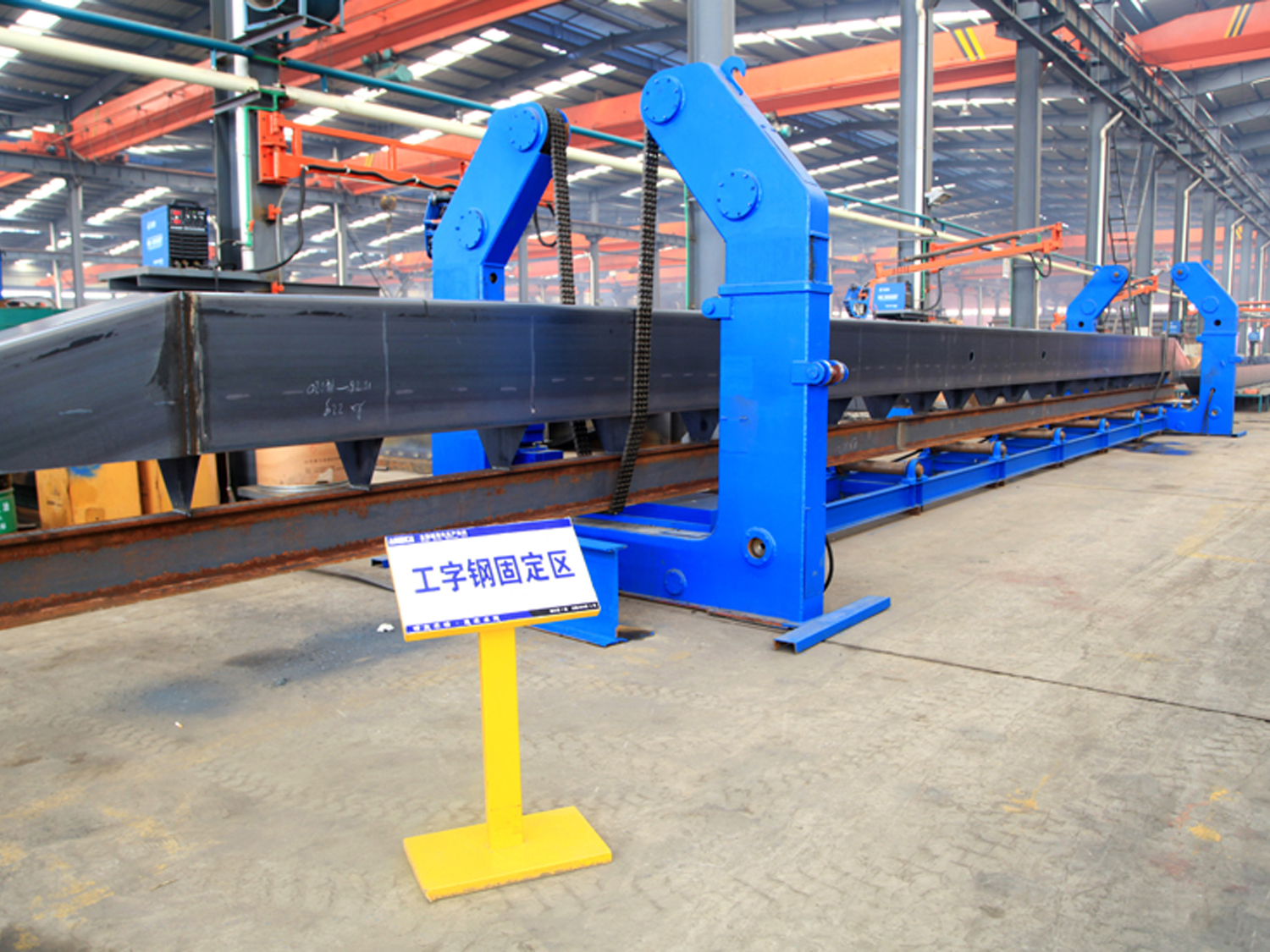

Our Factory

1

Production Workshop

2

Customer visit

3

Exhibition

4

ISO Certifiaction

5

CE Certifiaction

6

Our Services:

▶3 years warranty

▶Free distribution of wearing parts

▶Provide assemble videos before shipment

▶Technical support and field installation

Package and Delivery

Packing & Delivery terms:

▶Bridge: The bridge is the main component of the overhead crane and is typically shipped in sections. The sections may be packaged in wooden crates or steel frames to protect them during transport

▶Trolley: The trolley is the component that moves along the bridge and carries the hoist. It is usually shipped in a separate crate or box

▶Hoist: The hoist is the component that lifts and moves the load. It may be shipped separately or as part of the trolley assembly

▶Electrical Controls: The electrical controls for the crane are typically packaged in a separate crate or box. This includes the control panel, motor controllers, and wiring

▶End Trucks: The end trucks are the components that support the bridge and are responsible for moving the crane along the runway. They may be packaged separately or as part of the bridge assembly

▶Runway: The runway is the track that supports the crane and is typically shipped in sections. The sections may be packaged in wooden crates or steel frames to protect them during transport

FAQ

-

1How can I get a precise crane offer?

To providing you a precise crane offer efficiently, please kindly provide details as following:

Lifting capacity; material weight(unit as tonnage)

Lifting height; (unit as meter)

Crane span; the width of inquired crane(unit as meter)

Crane traveling length; when rail track/runway beam needed, traveling length shall be provided.

Working power; power source at site(unit as voltage, phase and Hz)

-

2Can I get your crane products with customized/personalized service?

A.Yes, Dowellcrane promise customized/personalized products are available for our clients all the time. Just freely let us know your special demands about the products, our engineering team will work on that.

-

3What should I do if I’m not able to install the crane after buying?

A.Freely contact us. Our engineering team available for oversea service with crane installation, inspection and commissioning.

-

4How long I can receive my crane products after my order placed?

A.Our production will be started once the payment confirmed. Below are timeline for whole procedure

-

5Do you have any additional service on warranty?

A. Yes, we provide “DowellCrae” service about the warranty, the warranty period will extend to two (2) years, full set of spare partsand working tools will delivered with crane for future replacement and maintenance.

FORM

GET THE BUSINESS TODAY

We really want to hear from you! Send us a message using the opposite table, or send us an email. We are

glad to receive your letter! Use the table on the right to send us a message