Double Girder KBK Crane

- Load 0.25-5 ton

- Boom Length 12m

- Warranty 3 years

- Color Customized

| Double Girder KBK Crane | Lifting Height:3-12m | Capacity:0.25-5 ton | Warranty:3 years |

| Travel Speed:8m-20/min | Span:4-16m | Power Supply:220V/380V 3Phase or Customized | Control Method:Remote Control |

Product Description

Double Girder KBK Crane

A double girder KBK crane is a type of modular overhead crane system that consists of two girders that are supported by a modular track system. This type of crane provides flexible and efficient lifting solutions for various industrial applications. It is commonly used in heavy-duty applications such as steel mills, foundries, and shipyards. They are designed to handle heavy loads and are ideal for applications where a single girder crane is not sufficient.

The double girder KBK crane is constructed with two girders that are supported by a modular track system. The girders are typically made of steel or aluminum and support the hoist and trolley that are used to lift and move loads. The crane can move along the track system, allowing it to cover a wide area within a facility.

Product Description

Product

Product Main Features

01:

Modular: can be easily customized to meet specific requirements

02:

Easy to install: can be relocated as needed

03:

Flexible: can adapt to changing production requirements

04:

Cost-effective: offer a high degree of efficiency in material handling operations

Safety Devices

- Overload protection: This device prevents overloading of the crane by stopping the hoist when the load capacity is exceeded.

- Anti-collision system: This device prevents collisions between the crane and other objects by stopping the crane when it detects an obstruction.

- Emergency stop button: This device allows the operator to stop the crane immediately in case of an emergency.

- Limit switches: These devices prevent the crane from travelling beyond its designated limits.

- Automatic braking system: This device ensures that the crane stops smoothly and safely when the hoist is lowered.

Parts Of Crane

About Us

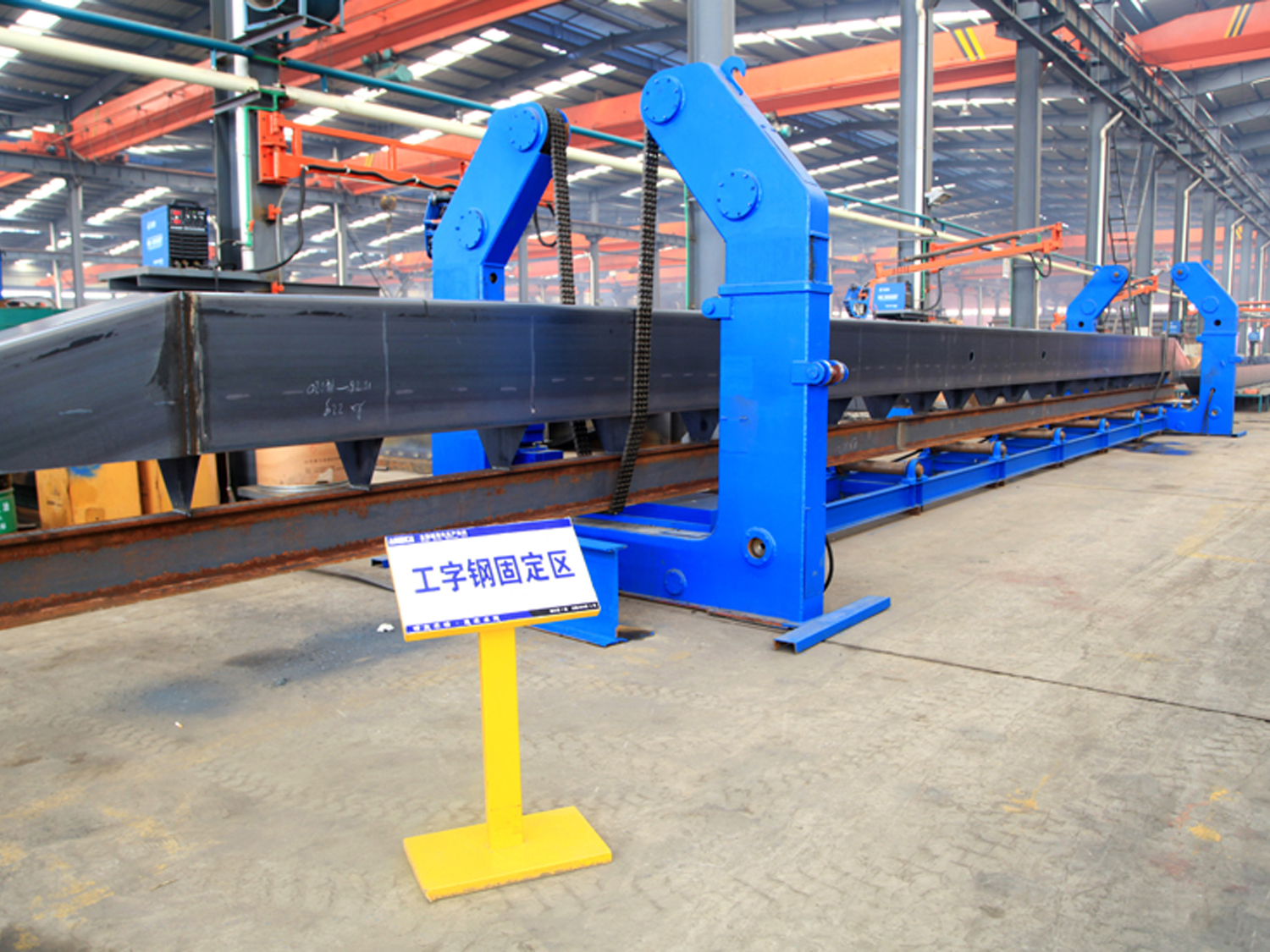

Our Factory

1

Production Workshop

2

Customer visit

3

Exhibition

4

ISO Certifiaction

5

CE Certifiaction

6

Our Services:

▶3 years warranty

▶Free distribution of wearing parts

▶Provide assemble videos before shipment

▶Technical support and field installation

Package and Delivery

Packing & Delivery terms:

▶Disassembly: The KBK crane is disassembled into its various components to prepare for packaging which involve removing the girder, hoist, trolley, and track system.

▶Protection: The components are then wrapped in protective materials, such as foam or bubble wrap, to prevent damage during transportation. The components may also be packed in sturdy cardboard boxes or wooden crates for additional protection.

▶Labeling: Each package is labeled with the component's name and identification number to ensure that they are reassembled correctly at their destination.

▶Documentation: provides documentation include assembly instructions and a parts list, to accompany the packaged components.

▶Shipping: The packaged components are shipped to the customer using a freight carrier or shipping service.

FAQ

-

1How can I get a precise crane offer?

To providing you a precise crane offer efficiently, please kindly provide details as following:

Lifting capacity; material weight(unit as tonnage)

Lifting height; (unit as meter)

Crane span; the width of inquired crane(unit as meter)

Crane traveling length; when rail track/runway beam needed, traveling length shall be provided.

Working power; power source at site(unit as voltage, phase and Hz)

-

2Can I get your crane products with customized/personalized service?

A.Yes, Dowellcrane promise customized/personalized products are available for our clients all the time. Just freely let us know your special demands about the products, our engineering team will work on that.

-

3What should I do if I’m not able to install the crane after buying?

A.Freely contact us. Our engineering team available for oversea service with crane installation, inspection and commissioning.

-

4How long I can receive my crane products after my order placed?

A.Our production will be started once the payment confirmed. Below are timeline for whole procedure

-

5Do you have any additional service on warranty?

A. Yes, we provide “DowellCrae” service about the warranty, the warranty period will extend to two (2) years, full set of spare partsand working tools will delivered with crane for future replacement and maintenance.

FORM

GET THE BUSINESS TODAY

We really want to hear from you! Send us a message using the opposite table, or send us an email. We are

glad to receive your letter! Use the table on the right to send us a message